+86-0577-86858771

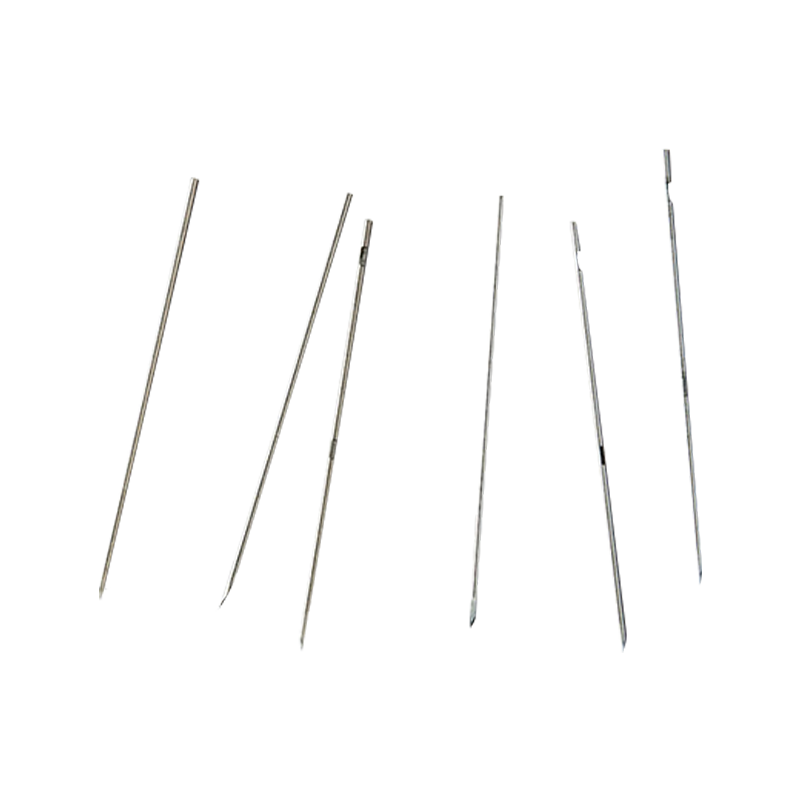

Needles are an essential part of modern medical practice and various industries, where precision and safety are critical. Whether it is an IV infusion needle, a medical sewing needle, or a micro blood collection needle, each type serves a distinct function that demands strict quality control throughout the manufacturing process. Ensuring the quality of these needles is fundamental to protecting patient safety, maintaining product reliability, and supporting effective medical procedures.

IV infusion needles are widely used for administering fluids, medications, and nutrients directly into a patient’s bloodstream. These needles must be manufactured to very precise standards to ensure they penetrate skin and veins smoothly without causing excessive trauma. Inconsistent dimensions, poor sharpness, or surface defects can advance to pain, bruising, or even infection. Therefore, stringent inspection of needle diameter, bevel angle, surface finish, and sterility is necessary to maintain a consistent product that healthcare providers can rely on. Even slight deviations can affect the flow rate of infusion and patient comfort, making quality control a priority.

Medical sewing needles have their own set of challenges in manufacturing. Used for suturing wounds, closing surgical incisions, or in specialized medical textiles, these needles require durability, flexibility, and sharpness. The needle’s tip must be fine enough to lessen tissue damage but also strong enough to resist bending or breaking under stress. Quality control involves rigorous testing for tensile strength, corrosion resistance, and tip geometry. Because these needles are often used in critical healing processes, any flaw could result in delayed recovery or complications. Additionally, medical sewing needles must be compatible with different types of sutures, requiring close attention to dimensions and surface treatment.

Micro blood collection needles are designed for collecting small volumes of blood with little discomfort. Their tiny size and delicate structure make manufacturing precision even more critical. Quality control in this area focuses heavily on the smoothness of the needle surface to reduce pain during insertion and on the accuracy of needle length and gauge. Since these needles are often used in laboratory diagnostics and blood testing, contamination risks must be lessened through strict sterilization protocols. Moreover, the connection between the needle and the collection device must be secure to prevent leakage or detachment during use. Any compromise in these aspects could affect test results or patient safety.

Across all these types of needles, quality control does not end with the physical attributes alone. The manufacturing environment must adhere to rigorous cleanliness and sterility standards to prevent contamination. Automated inspection systems, including laser measurement and microscopic imaging, are increasingly common to detect defects that are not visible to the naked eye. Batch testing for mechanical properties and chemical composition also plays a crucial role in ensuring that every needle meets the necessary standards before it reaches medical professionals or consumers.

Moreover, regulatory compliance is an integral part of quality control in needle manufacturing. Adhering to industry guidelines and national standards ensures that products are safe and effective for their intended use. Manufacturers must document each stage of production, from raw material sourcing to final packaging, to provide traceability and accountability. This systematic approach helps identify issues early and supports continuous improvement in manufacturing processes.

In conclusion, quality control in needle manufacturing is a vital process that directly impacts the safety and efficacy of medical treatments. From IV infusion needles to medical sewing needles and micro blood collection needles, careful attention to material selection, design precision, sterility, and compliance is essential. The consequences of inadequate quality control can range from minor discomfort to serious health risks, underscoring the importance of maintaining strict standards throughout production. As medical technology advances and demands for precision grow, the role of quality control will continue to be central in delivering reliable and safe needle products to the healthcare industry.

Wenzhou Kangyu Medical TREATMENT

+86-0577-86858771

+86-13957709138

No. 626 Airport Avenue, Longwan District, Wenzhou City, Zhejiang Province, China

Contact Us