+86-0577-86858771

The evolution of medical procedures, ranging from advanced drug delivery to minimally invasive surgery, relies heavily on the continuous refinement of its fundamental tools. Special medical needles are no longer simple, generic instruments but are instead the product of deliberate and nuanced design engineering. Their development is influenced by a confluence of factors that extend beyond basic sharpness, integrating clinical insight, material innovation, and precision manufacturing often seen in high-specification industrial needles. Understanding these shaping forces reveals how a carefully considered design directly supports clinical intent and patient care.

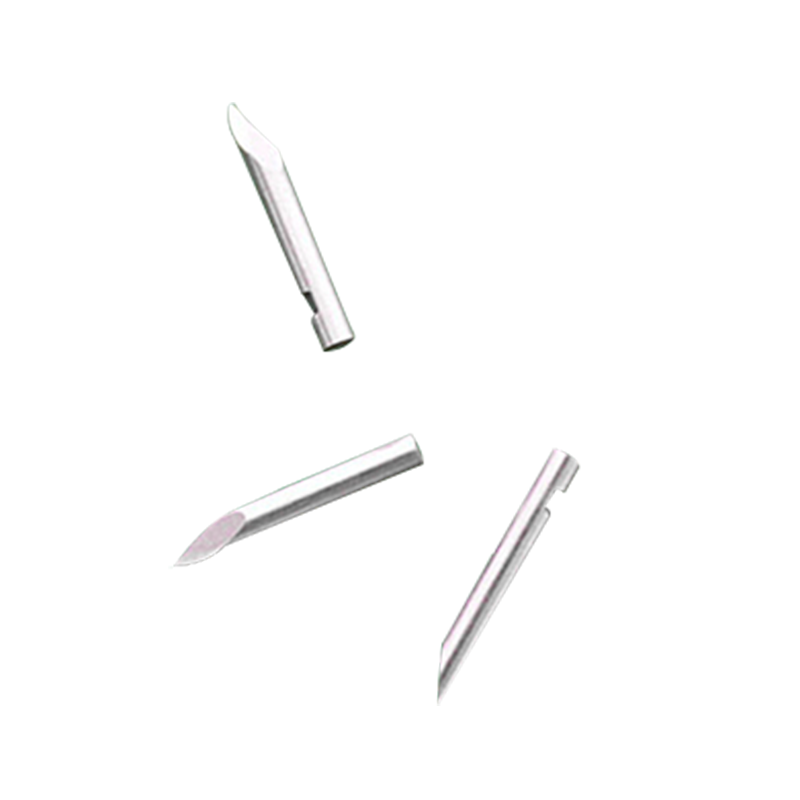

The foremost factor influencing the design of a special medical needle is the specific clinical procedure it is intended to perform. Each application presents a distinct set of requirements that dictate form and function. For instance, a needle designed for a spinal tap requires a different length, gauge, and tip geometry compared to one used for intradermal vaccinations or bone marrow aspiration. The design process begins with a detailed analysis of the target tissue, the desired depth of penetration, the viscosity of the substance being delivered or aspirated, and the sensitivity of the surrounding anatomy. This procedure-centric approach ensures the tool is fit for its precise purpose, aiming to support procedural accuracy and accommodate anatomical considerations.

The choice of material is a critical design decision that balances mechanical performance with biological safety. Modern special medical needles often utilize specific grades of stainless steel for their strength and ductility, or nickel-titanium alloys (Nitinol) for unique properties like shape memory and super-elasticity, which are valuable in navigating complex vascular pathways. Beyond metal, specialized polymer coatings or entirely polymer-based needles are designed for specific imaging compatibility or to alter surface lubricity. Each material is selected not only for its sharpness and resistance to deformation but also for its proven biocompatibility, ensuring it can perform as intended without adversely interacting with biological tissues or affecting sensitive therapeutic agents.

The transition from a design concept to a reliable clinical tool is achieved through high-precision manufacturing. The dimensional tolerances for features such as inner and outer diameter, wall thickness, and bevel angle are exceptionally tight, often mirroring standards found in the production of industrial needles for fine instrumentation. Advanced processes like laser cutting, micro-machining, and electropolishing are employed to achieve a sharp, consistent tip and a smooth lumen surface. This attention to manufacturing detail aims to provide consistent performance from one needle to the next, which is fundamental for predictable tissue interaction, fluid flow dynamics, and overall procedural control for the clinician.

The design of a special medical needle extends beyond the needle cannula itself to include its interface with the clinician and any associated device. Hub design, attachment mechanisms for syringes or tubing, and handling features are shaped by ergonomic principles to support secure grip and control during use. Furthermore, many needles are designed as integral components of larger systems, such as auto-injectors, biopsy guns, or catheter introducers. This systems-based approach requires the needle design to seamlessly integrate with these devices, ensuring proper function, safety, and ease of use. The design must consider how the needle is presented, deployed, and shielded, both before and after use.

From the outset, the design of any special medical needle is developed within a framework of stringent regulatory requirements and international standards. These guidelines govern aspects like material safety, mechanical testing, labeling, and validation of sterilization methods. Consequently, design decisions must account for the needle's ability to withstand sterilization processes—such as autoclaving, gamma irradiation, or ethylene oxide exposure—without compromising its critical attributes. The design must also facilitate proper cleaning and sterilization if it is intended for reuse, or ensure integrity and sterility in single-use, pre-packaged formats. This regulatory environment ensures that design innovation is consistently paired with verified safety and quality.

The form of a modern special medical needle is, therefore, a direct reflection of a complex and iterative design process. It synthesizes clinical necessity with advanced materials science, precision fabrication, user-centered ergonomics, and rigorous quality assurance. This multidisciplinary approach results in instruments that are purposefully crafted to meet the nuanced demands of contemporary medicine. By focusing on these foundational design factors, developers can create tools that effectively support healthcare professionals in performing procedures with a focus on clinical objectives, ultimately contributing to the broader goals of modern patient management and treatment.

Wenzhou Kangyu Medical TREATMENT

+86-0577-86858771

+86-13957709138

No. 626 Airport Avenue, Longwan District, Wenzhou City, Zhejiang Province, China

Contact Us