+86-0577-86858771

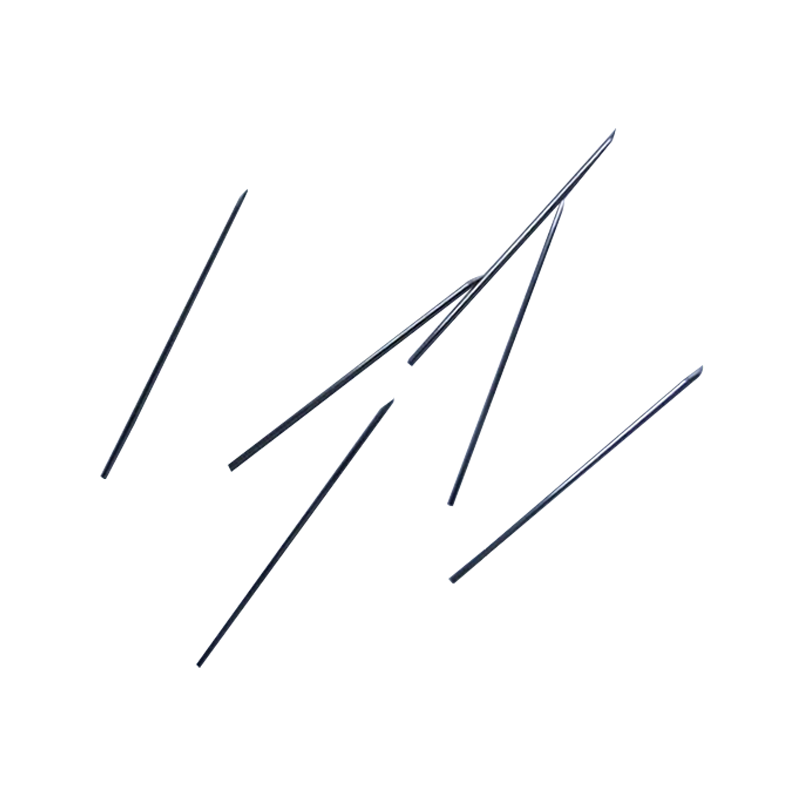

The distinction between specialized medical needles and industrial needles may appear clear. However, a closer examination reveals that the engineering and material principles behind many industrial needle designs align closely with the demanding requirements of certain medical procedures. This overlap raises a pertinent question: what characteristics allow certain industrial-grade needles to be suitable for medical applications? The answer lies not in a direct substitution, but in a shared foundation of precision, material integrity, and functional design that meets stringent operational criteria.

At the core of both specialized medical needles and certain industrial needles is a commitment to high-grade materials. Stainless steel alloys, particularly those with specific compositions offering strength and corrosion resistance, are common. The focus on material consistency, durability, and biocompatibility is paramount. Industrial needles intended for fine instrumentation or long-term use in controlled environments often undergo similar rigorous material selection and testing processes. This ensures they can maintain structural integrity and resist degradation, which is a fundamental requirement when considering any instrument for potential medical use, where material failure is not an option.

Medical applications demand exceptional consistency and tolerance control. Every needle must perform identically to ensure predictable outcomes and maintain safety standards. This is an area where advanced industrial needle manufacturing excels. Techniques such as precision grinding, laser cutting, and automated quality inspection, developed for high-performance industrial sectors, produce components with exacting dimensional accuracy and surface finish. When such manufacturing discipline is applied, the resulting needles achieve the uniformity required for medical devices, ensuring that each unit performs its intended function with a high degree of repeatability.

While specialized medical needles are designed with anatomical and procedural specifics in mind, industrial needles are engineered for functional challenges such as precise fluid handling, penetrating specific materials. A beveled tip on an industrial needle, designed to reduce insertion force in a technical fabric, shares a functional principle with a medical needle tip designed for tissue penetration. Similarly, customized lumen designs or specialized coatings developed to manage flow or reduce friction in industrial settings can be adapted to meet specific medical delivery or sampling needs. The suitability arises from this design philosophy focused on solving a precise mechanical challenge.

A critical factor for any medical device is its ability to withstand sterilization processes without compromising function. Many industrial needles, particularly those used in pharmaceutical, biotechnology, or food processing industries, are already designed for cleanroom use or must endure sterilization for aseptic production. Their construction often considers exposure to autoclaves, chemical sterilants, or radiation. This inherent capability to be effectively sterilized and maintain cleanliness is a significant factor that supports the transition of suitable industrial needle designs into regulated medical environments.

In developing medical devices, especially for specialized or emerging applications, leveraging existing, well-understood industrial components can offer practical advantages. Utilizing a proven industrial needle design that already meets key criteria for material, precision, and sterility can streamline development timelines. It allows engineers and researchers to focus on integrating the needle into a larger system or adapting it for a novel clinical purpose. This approach can also contribute to managing production costs, making certain advanced needle technologies more accessible for medical innovation without compromising on the essential qualities of performance and safety.

Wenzhou Kangyu Medical TREATMENT

+86-0577-86858771

+86-13957709138

No. 626 Airport Avenue, Longwan District, Wenzhou City, Zhejiang Province, China

Contact Us