+86-0577-86858771

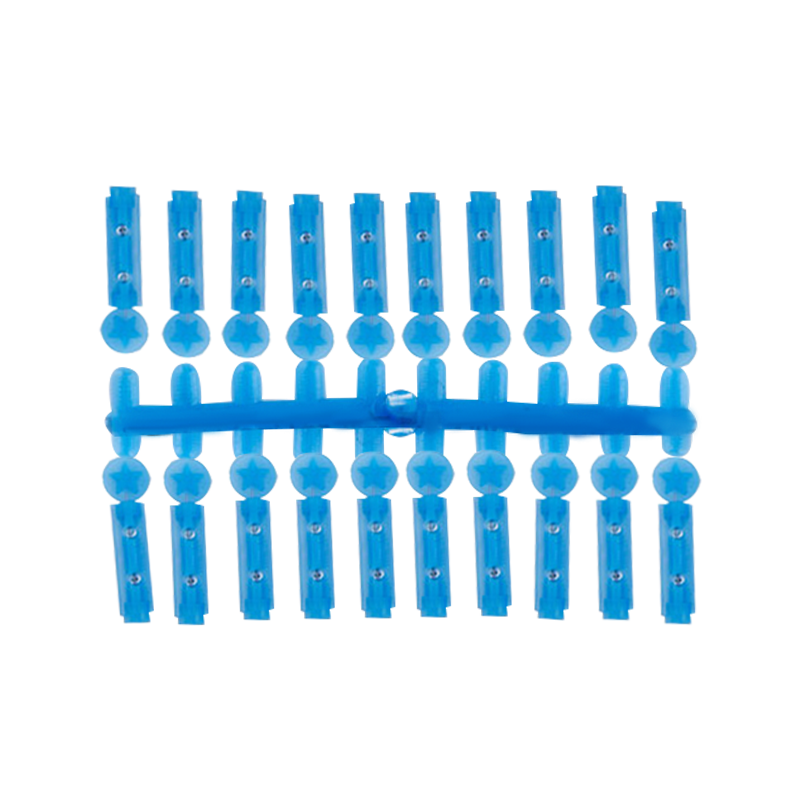

Maintaining consistent sterility is a fundamental concern for any Medical Needles Factory, especially when producing a range of products such as Various Fancy Needles. Ensuring that each needle meets hygiene and safety requirements involves a combination of controlled manufacturing environments, rigorous monitoring, and adherence to established procedures. Understanding these processes can help healthcare professionals and distributors make informed decisions when selecting suppliers.

A key element in maintaining sterility is the design and management of the production area. Factories typically use cleanrooms with regulated air flow, temperature, and humidity. These conditions help prevent contamination from particles or microorganisms during the needle assembly and packaging process. Workers are required to wear protective clothing and follow strict hygiene protocols to reduce the risk of external contaminants. For Various Fancy Needles, which may have specialized tips or designs, additional precautions may be taken to protect sensitive components.

Different types of needles may require distinct sterilization techniques depending on the materials and intended use. Common methods include ethylene oxide gas, gamma irradiation, and autoclaving. Each method has a standardized procedure to ensure that sterilization penetrates all surfaces and internal components effectively. Factories often run routine tests on sample batches to confirm that sterility has been achieved and that no residues from the sterilization process remain on the needles. This ensures the safety of both patients and practitioners.

Quality control is integrated throughout the production cycle. Visual inspections, dimensional measurements, and mechanical testing help detect defects that could compromise sterility or usability. For example, needles with unusual shapes or designs—such as some Various Fancy Needles—may require additional checks to ensure coatings, sharpness, or tips remain consistent after sterilization. Statistical sampling and documentation support traceability, allowing any issues to be traced back to the source and addressed promptly.

Once sterilized, needles must be packaged to maintain their sterile state until use. Factories employ sealed, tamper-evident packaging materials and automated systems to reduce human contact. Temperature and humidity conditions are often monitored during storage and shipment. For needles with intricate designs, packaging may include additional supports or protective layers to prevent deformation or damage. Proper labeling ensures that healthcare providers can identify the product, its expiration date, and any relevant handling instructions.

Regulatory compliance is another factor that ensures consistent sterility. Medical needle manufacturers adhere to standards set by health authorities, such as ISO 13485 for medical devices. Regular internal audits, external inspections, and documentation reviews help verify that processes are followed accurately. Continuous monitoring of equipment, sterilization cycles, and environmental parameters ensures that any deviations are detected and corrected in a timely manner.

A well-trained workforce plays a critical role in maintaining sterile production. Employees receive training on hygiene protocols, machine operation, and emergency procedures. Standard operating procedures (SOPs) guide every step of needle production, from raw material handling to final packaging. When staff understand the reasoning behind each process, adherence improves, and the likelihood of contamination decreases. For factories producing Various Fancy Needles, specialized training may cover unique production steps or handling techniques.

Maintaining records of production batches, sterilization cycles, and inspection results is important for quality assurance. Traceability allows manufacturers to address any issues that arise after distribution and provides healthcare providers with confidence in the product’s handling history. In cases where needles are customized or have uncommon features, detailed documentation ensures that every unit meets the established sterility standards.

Wenzhou Kangyu Medical TREATMENT

+86-0577-86858771

+86-13957709138

No. 626 Airport Avenue, Longwan District, Wenzhou City, Zhejiang Province, China

Contact Us