+86-0577-86858771

Innovation in the medical device field continues to be driven by collaboration among healthcare professionals, researchers, engineers, and manufacturers. These partnerships help create solutions that improve patient outcomes, increase procedural efficiency, and ensure safety. The development and refinement of tools such as needles used in various medical applications exemplify how cooperation fosters progress.

Take, for example, the needle gauge for iv fluids. Selecting the appropriate needle gauge is essential for delivering intravenous fluids safely and effectively. Different gauges influence the flow rate and patient comfort. A thinner needle may reduce pain but might not be suitable for rapid fluid administration, while a thicker gauge allows faster flow but can cause more discomfort. Innovations in materials and design have aimed to strike a better balance, improving both patient experience and clinical effectiveness. This process often involves feedback from clinicians who regularly perform IV insertions, ensuring the needle design meets practical demands.

Similarly, medical stitching needle medical used in medical suturing have evolved through joint efforts between surgeons and medical device engineers. The design of a stitching needle must take into account the type of tissue it will pass through, the surgical technique employed, and the ease of handling by the surgeon. The curvature, sharpness, and size of the needle all play critical roles in the success of wound closure. Collaborative development ensures that these needles support diverse surgical needs, whether in delicate microsurgery or general wound repair. Moreover, advancements in coating technologies have made these needles glide more smoothly through tissue, reducing trauma and improving healing times.

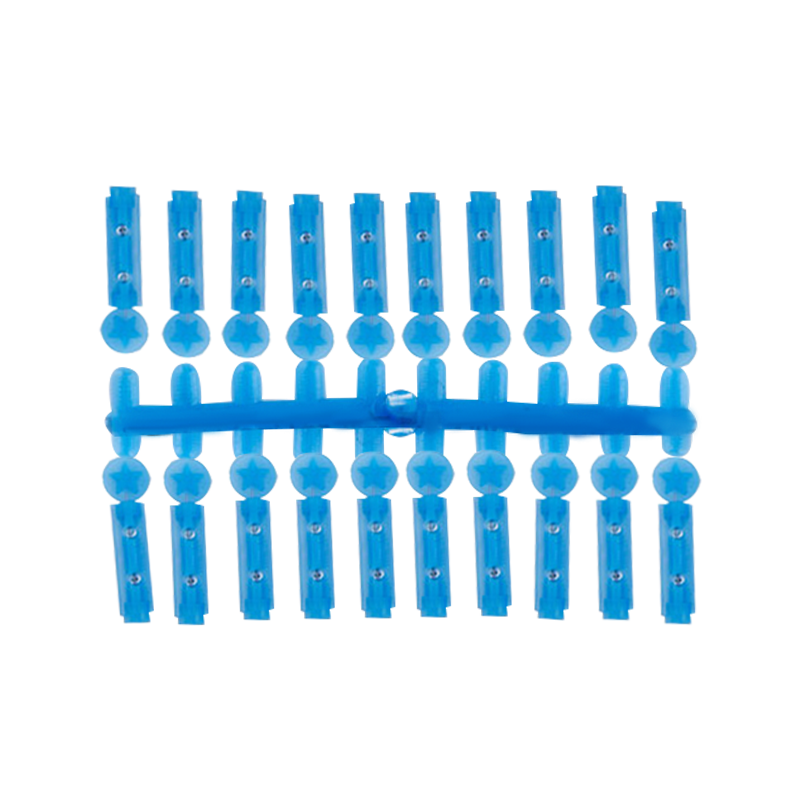

Another area that benefits from collaborative innovation is biopsy needles, particularly the side hole biopsy needle. This specialized needle features an opening on the side near the tip, allowing for improved tissue sampling during diagnostic procedures. The design helps in obtaining better quality samples with less patient discomfort and procedural risk. Input from pathologists, radiologists, and device manufacturers has been key in refining these needles. Their collaboration has contributed to enhancements in needle flexibility, material strength, and sample capture mechanisms, ultimately supporting more accurate diagnoses.

The process of innovating medical needles and related devices is preciously linear. It often involves iterative cycles of prototyping, testing, and clinical trials. Engineers may develop new designs or materials, which clinicians then evaluate in real-world settings. Feedback about usability, patient response, and performance guides further refinements. This loop is essential to ensure that devices not only meet theoretical standards but also perform well in practice.

Beyond physical design, collaboration extends into regulatory and manufacturing realms. Medical devices must comply with stringent safety standards and regulatory requirements. Early involvement of regulatory experts in the development process helps anticipate challenges and streamline approvals. Manufacturers, meanwhile, work closely with designers to ensure that innovations can be produced consistently and economically at scale. These multi-disciplinary efforts reduce the risk of costly delays and ensure that new devices can reach patients promptly.

The importance of collaboration in medical device innovation is also evident in educational initiatives. Sharing knowledge across specialties encourages new ideas and fosters understanding of clinical needs. Conferences, workshops, and cross-disciplinary teams provide platforms where experts exchange insights and explore emerging technologies. This environment helps drive incremental improvements and sometimes sparks breakthrough concepts.

Advancing medical devices such as needle gauges for IV fluids, stitching needles, and side hole biopsy needles depends heavily on collaboration among various stakeholders. The convergence of clinical experience, engineering expertise, regulatory guidance, and manufacturing capability shapes devices that are practical, safe, and beneficial to patients. While innovation requires technical skill, it is the shared commitment and communication across disciplines that truly enable meaningful progress in medical technology.

Wenzhou Kangyu Medical TREATMENT

+86-0577-86858771

+86-13957709138

No. 626 Airport Avenue, Longwan District, Wenzhou City, Zhejiang Province, China

Contact Us