+86-0577-86858771

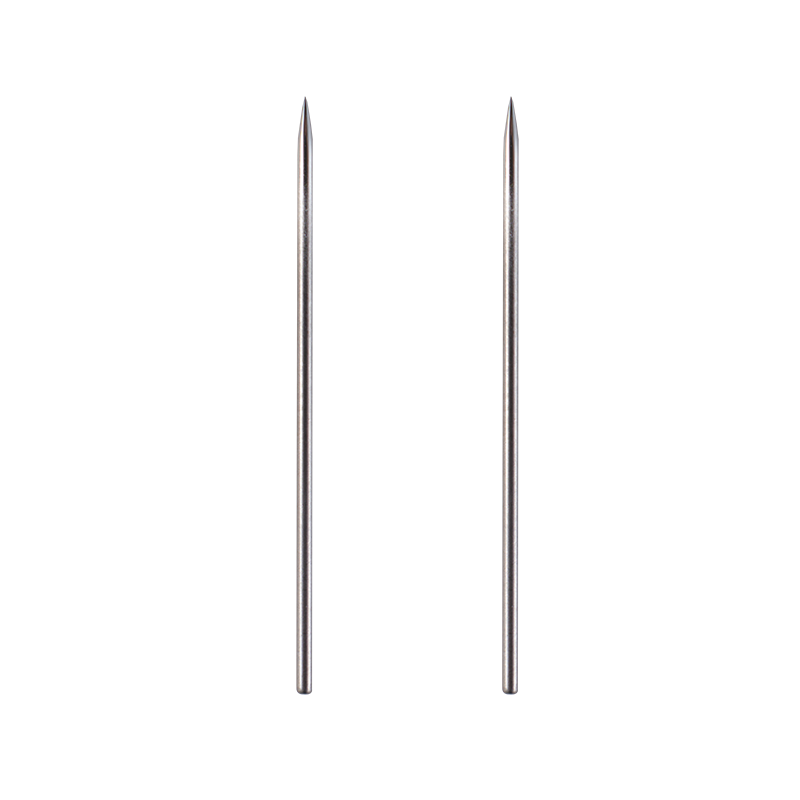

Infusion needles play a crucial role in medical practice, facilitating everything from routine blood draws to delivering medications intravenously. Among the various types, vacutainer needles, needles for injections, and needle with side hole are widely used due to their specific functionalities. To appreciate their significance in healthcare, it helps to understand how these needles are produced, the materials involved, and the precision required during manufacturing.

The journey of an infusion needle begins with selecting high-quality stainless steel wire. Stainless steel is chosen because of its corrosion resistance, strength, and biocompatibility, making it safe for use inside the human body. The wire typically undergoes a straightening and cleaning process to prepare it for further steps. Cleanliness at this stage is essential, as any impurities can affect the needle's sharpness and safety.

Once the wire is ready, it moves to the cutting and shaping stage. For a Vacutainer needle, which is commonly used for blood collection, the dimensions need to be precise. These needles are designed to pierce the skin and vein smoothly, connecting securely to the Vacutainer system that allows for blood to be drawn without exposure to air or contaminants. The needle must have a sharp bevel to reduce pain and tissue damage upon insertion. This is achieved through careful grinding and polishing.

Needles for injections, on the other hand, can vary in length and gauge depending on their application—ranging from subcutaneous injections to intramuscular ones. The manufacturing process adjusts accordingly to meet these specifications. After cutting the wire to length, the tips are ground to form a sharp point that can penetrate the skin easily. The surface finish is polished for less friction, which helps reduce discomfort during use.

A particular type of infusion needle worth mentioning is the needle with a side hole. Unlike conventional needles that have a single opening at the tip, these needles feature an additional opening along the side near the tip. This design can facilitate smoother fluid flow, reduce vein trauma, and allow for more controlled medication delivery. Producing needles with side holes requires advanced precision machinery to drill or punch the side openings without compromising the needle’s structural integrity.

After shaping and adding features like side holes, the needles undergo a thorough cleaning process. This usually involves ultrasonic cleaning, which removes any microscopic debris or oils left from manufacturing. Sterility is paramount since these needles will come into direct contact with blood or bodily fluids. Following cleaning, needles are inspected for any defects such as burrs, irregularities in the bevel, or inconsistencies in diameter.

The next stage involves coating and sterilization. Some infusion needles are coated with silicone or other lubricants to improve insertion comfort. The coating process needs to be uniform and carefully controlled to avoid any excess that might interfere with the needle's performance. Sterilization is generally performed using gamma radiation, ethylene oxide gas, or steam, depending on the manufacturer’s protocols. This step ensures that the needles are free from any harmful microorganisms before packaging.

Packaging also plays a vital role in maintaining needle safety and sterility. Needles are typically packaged individually in sealed blister packs or sterile pouches. For vacutainer needles, the packaging may include attached hubs compatible with blood collection systems, ensuring ease of use for healthcare professionals. The packaging must protect the needle from damage during transportation and storage, as even a slight bend or contamination can render the needle unusable.

Throughout the production process, quality control measures are applied at multiple stages. Dimensional checks, sharpness tests, and sterility validation are standard. These procedures help confirm that the needles meet regulatory standards and perform reliably in clinical settings.

In summary, the production of infusion needles such as Vacutainer needles, needles for injections, and needles with side holes involves multiple precise and controlled steps. From selecting raw materials to final packaging, each stage is designed to ensure safety, reliability, and patient comfort. Understanding this process highlights the complex balance between engineering and medical needs required to produce these small but essential medical devices.

Wenzhou Kangyu Medical TREATMENT

+86-0577-86858771

+86-13957709138

No. 626 Airport Avenue, Longwan District, Wenzhou City, Zhejiang Province, China

Contact Us