+86-0577-86858771

The global medical needle manufacturing industry plays a crucial role in modern healthcare, providing essential tools that support a variety of medical procedures worldwide. Among the many types of needles produced, butterfly blood collection needles, syringe needles, and closed-end side port needles stand out as common and vital instruments, each serving distinct purposes across clinical environments. Understanding the landscape of these products offers insight into the ongoing advancements and challenges faced by manufacturers in this sector.

Butterfly blood collection needles, sometimes known simply as winged infusion sets, are widely used in phlebotomy and intravenous therapy. Their design includes flexible "wings" that allow healthcare professionals to achieve greater control and precision when accessing veins, which is particularly beneficial for patients with small or fragile veins, such as children or the elderly. The tubing connected to the needle also enhances maneuverability and reduces patient discomfort. Manufacturers focus on producing butterfly needles that balance sharpness with patient comfort, ensuring the needle penetrates the vein smoothly without causing unnecessary trauma. The materials used are often chosen for biocompatibility and sterility, which are critical to preventing infections and ensuring patient safety.

Syringe needles form another cornerstone of medical needle production. These needles come in various sizes and gauges to accommodate different injection requirements, ranging from intramuscular injections to subcutaneous and intravenous administrations. Syringe needles must meet strict quality standards to maintain consistency in sharpness, strength, and reliability. Precision manufacturing is essential to less pain during injection and to prevent needle bending or breaking during use. With the rise of self-administered medications, such as insulin for diabetes, the demand for user-friendly syringe needles has influenced design trends, pilot to features like thinner walls and ergonomic hubs that facilitate easier handling and injection.

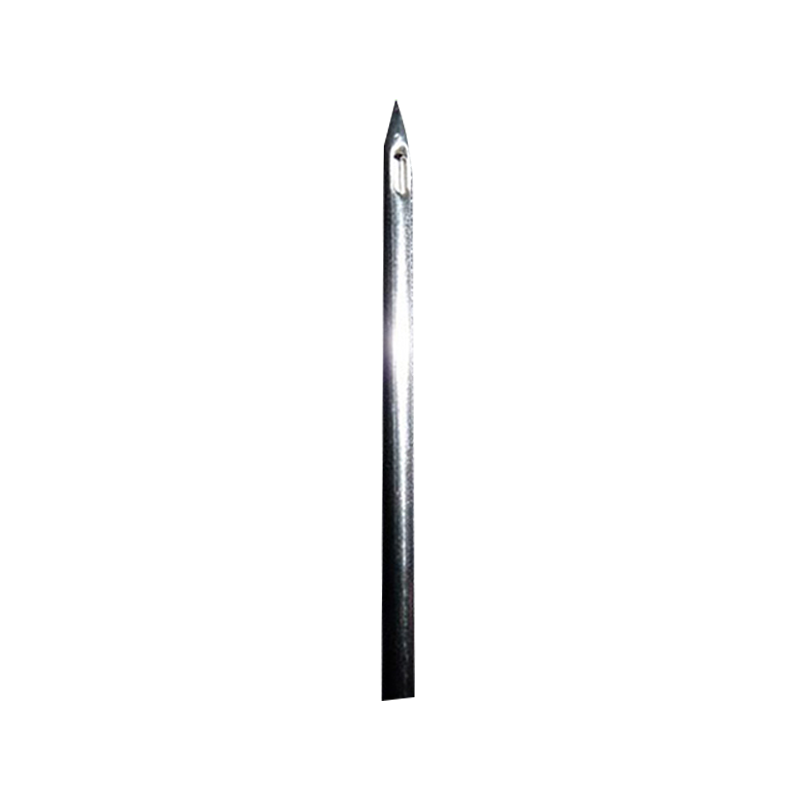

Closed-end side port needles represent a specialized category designed primarily for specific medical procedures requiring controlled fluid flow. These needles feature a closed tip with a side opening near the end, which allows fluid to exit or enter the vessel or tissue without penetrating directly through the needle’s tip. This design is advantageous in applications such as blood sampling, drug delivery, or aspiration, where precise directional control of fluids is necessary. The closed-end side port needle’s structure helps reduce damage to vessels or tissues and can decrease the risk of unwanted leakage. Manufacturers of these needles focus on ensuring the side port is ideally positioned and engineered to provide consistent performance under varying clinical conditions.

Globally, the production of medical needles has evolved alongside advances in medical technology and materials science. Manufacturers operate under stringent regulatory environments that demand compliance with international standards for sterility, biocompatibility, and mechanical performance. These standards aim to protect both patients and healthcare workers from infections and injuries. To meet these demands, manufacturers invest heavily in cleanroom facilities, automated production lines, and rigorous quality control measures. The drive for improved patient outcomes pushes innovation, with research directed at reducing needle-related pain and anxiety while enhancing safety features such as needle shielding or retractable mechanisms to prevent accidental needle-stick injuries.

Supply chains for medical needles are complex and global in nature. Raw materials such as stainless steel and specialized polymers are sourced from various regions, and production is often distributed across multiple countries. This global interconnection requires manufacturers to be agile and responsive to shifts in market demand and regulatory changes. Additionally, fluctuations in healthcare funding and geopolitical factors can influence the availability and pricing of medical needles, affecting hospitals, clinics, and other healthcare providers worldwide.

In recent years, environmental concerns have also influenced manufacturing practices. The widespread use of disposable needles raises questions about medical waste and sustainability. Some manufacturers have begun exploring biodegradable materials and designs that reduce waste without compromising safety or performance. While these efforts are in the early stages, they reflect an increasing awareness of the environmental impact associated with single-use medical devices.

The future of medical needle manufacturing will likely continue to blend traditional craftsmanship with innovative materials and smart technologies. Enhanced coatings to reduce friction, sensors integrated into needles for feedback during procedures, and designs tailored for new therapeutic techniques are all areas of ongoing development. The ability to adapt to the evolving needs of healthcare professionals and patients will remain a defining factor for manufacturers in this field.

In summary, the global landscape of medical needle manufacturers is marked by steady progress and adaptation to clinical, regulatory, and environmental demands. Butterfly blood collection needles, syringe needles, and closed-end side port needles each fulfill specific roles within healthcare, and their production reflects a balance of precision engineering, safety considerations, and practical usability. While challenges remain, the ongoing evolution of materials and manufacturing technologies promises continued improvements that support effective and safe medical care around the world.

Wenzhou Kangyu Medical TREATMENT

+86-0577-86858771

+86-13957709138

No. 626 Airport Avenue, Longwan District, Wenzhou City, Zhejiang Province, China

Contact Us