+86-0577-86858771

The medical industry continuously seeks ways to improve patient care while addressing environmental concerns. One area gaining increasing attention is the production of medical needles, including blood sample needles, injection needles, and stainless steel syringe needles. As healthcare systems grow worldwide, the demand for these needles rises steadily, making sustainability in their manufacturing an important consideration. Embracing sustainable practices in this sector not only reduces environmental impact but also contributes to safer and more responsible healthcare delivery.

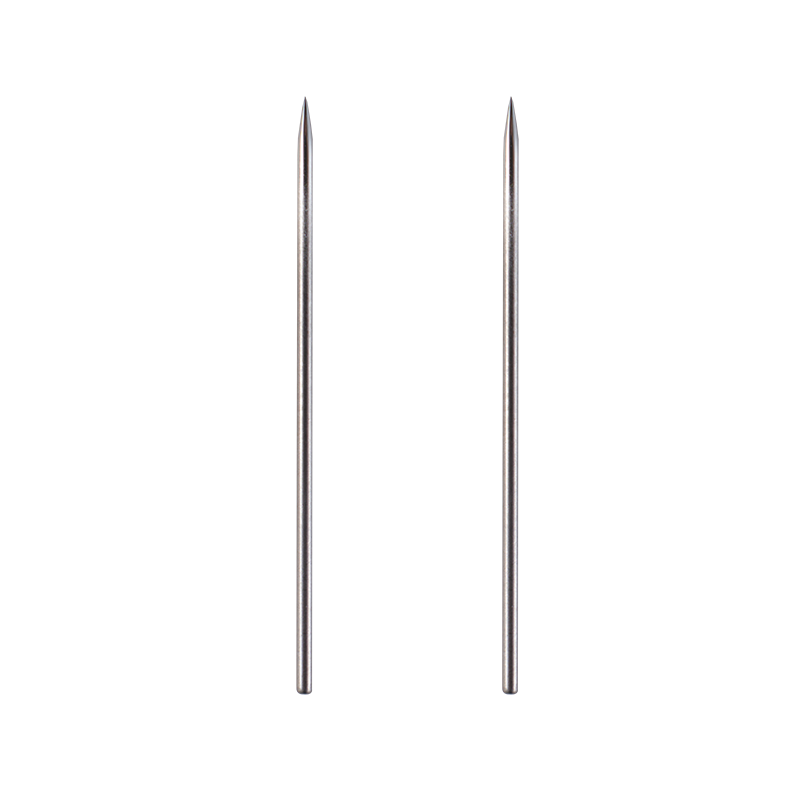

Medical needles play a vital role in diagnostics and treatment. Blood sample needles, for instance, are specifically designed to obtain patient blood safely and efficiently. Injection needles, on the other hand, facilitate the administration of medications, vaccines, or other therapeutic substances. Stainless steel syringe needles are valued for their durability, precision, and corrosion resistance, which are essential qualities in medical procedures. Despite their critical function, the environmental footprint of producing and disposing of these needles has raised concerns that manufacturers and healthcare providers are starting to address.

One of the primary areas for improvement in sustainable needle production is material selection. Stainless steel is widely used due to its strength and sterilizability, yet its production can be resource-intensive. To mitigate this, some manufacturers focus on sourcing stainless steel from suppliers who practice responsible mining and recycling. Incorporating recycled stainless steel into needle production can significantly reduce raw material consumption and lower carbon emissions associated with mining and processing. Additionally, research is ongoing to develop alternative materials or coatings that maintain the necessary safety standards while reducing environmental impact.

Manufacturing processes themselves also offer opportunities for sustainability. By optimizing production lines to reduce waste, energy consumption, and water usage, companies can reduce their ecological footprint. For example, precision cutting and stamping techniques can ensure that metal use is efficient, leaving less scrap material behind. Waste metal can be collected and recycled back into the supply chain, closing the loop on material use. Advances in automation and quality control reduce the rate of defective products, which means fewer discarded needles and less resource waste.

Packaging is another important factor in sustainable medical needle production. While needles require sterile packaging to maintain safety and hygiene, there is a growing emphasis on using recyclable or biodegradable materials for packaging components. Lightweight packaging reduces transportation emissions, and designs that use fewer materials contribute to waste reduction. Some suppliers are exploring innovations such as compostable films or paper-based packaging that can safely protect needles while offering a reduced environmental burden.

End-of-life management of medical needles is a crucial aspect that ties into sustainability. Due to infection risks, needles must be disposed of as biohazardous waste, which poses challenges for recycling and waste reduction. However, strategies such as safe collection systems and specialized recycling programs can help recover materials from used needles. In some regions, medical waste is treated to safely extract metals for reuse. Encouraging healthcare facilities to adopt proper disposal and recycling protocols is key to less environmental impact.

Sustainable practices in medical needle production also extend to social responsibility and regulatory compliance. Manufacturers are increasingly attentive to workplace safety, ethical sourcing of materials, and adherence to environmental regulations. This holistic approach ensures that sustainability is integrated throughout the entire supply chain rather than focusing solely on product design. Partnerships between suppliers, healthcare providers, and regulatory bodies can help set and maintain standards that promote sustainability without compromising patient safety.

The future of sustainable medical needle production likely involves continued innovation and collaboration. Emerging technologies, such as additive manufacturing (3D printing), may allow for more customized needles with less material waste. Research into biodegradable or bio-based materials could provide alternatives to traditional stainless steel components. In addition, digital tracking and supply chain transparency tools can help verify sustainable practices from raw material extraction through to final product delivery.

In summary, sustainability in the production of blood sample needles, injection needles, and stainless steel syringe needles is becoming an essential aspect of modern healthcare manufacturing. By improving material sourcing, refining manufacturing processes, innovating packaging, and addressing waste management, the medical needle industry can contribute to reducing environmental impacts while maintaining safety and quality. The balance between sustainability and functionality requires ongoing effort but holds promise for a future where healthcare products are not only effective but also environmentally considerate.

Wenzhou Kangyu Medical TREATMENT

+86-0577-86858771

+86-13957709138

No. 626 Airport Avenue, Longwan District, Wenzhou City, Zhejiang Province, China

Contact Us