+86-0577-86858771

Across various industries, components such as industrial needles and stainless steel capillaries are selected not only for their precision but also for their ability to withstand demanding environments. When systems involve the transfer of corrosive fluids, the choice of materials becomes critical to maintaining efficiency and preventing costly equipment failures. Stainless steel capillaries have emerged as a practical option, providing strength and resistance that support long-term use in fluid handling systems.

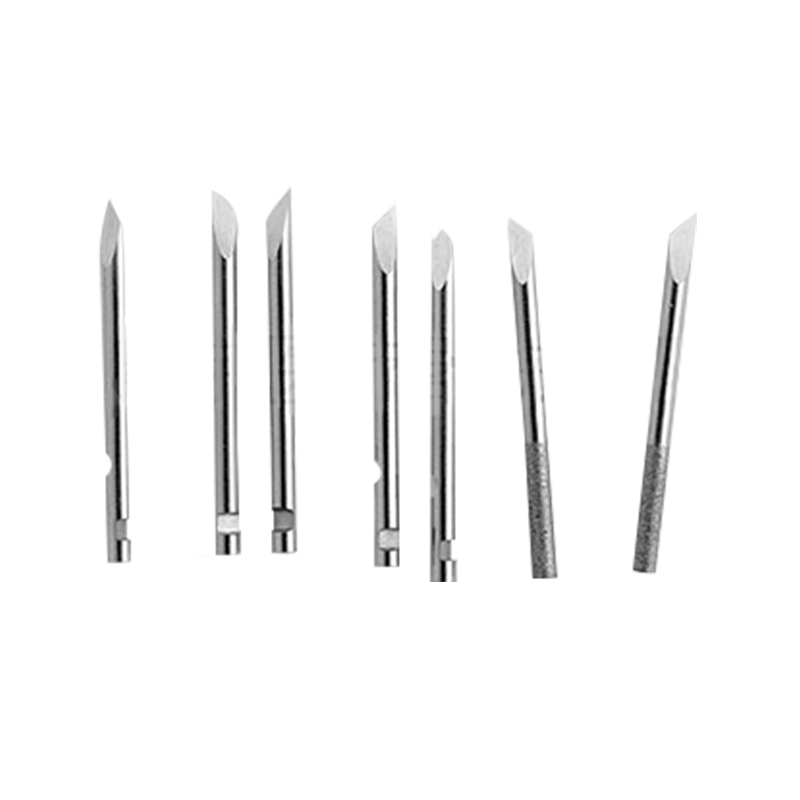

Stainless steel capillaries are fine tubes designed to manage the controlled movement of gases and liquids through a system. Their uniform size and smooth inner surface make them suitable for laboratory testing, medical technology and industrial operations. When paired with industrial needles, these capillaries help regulate flow and provide accuracy in applications where exact measurements and consistent delivery are required. For corrosive fluids, the durability of stainless steel reduces the risks associated with leaks, contamination, or structural breakdown.

Corrosive fluids, including acids, alkalis, and certain solvents, can cause degradation in materials that are not engineered to resist chemical reactions. Plastic tubes, while lightweight and flexible, may soften or weaken when exposed to aggressive chemicals. Similarly, non-alloy metals can corrode quickly, leading to premature system failure. The result is not only a loss of material integrity but also potential contamination of the fluid being transferred. Selecting a material like stainless steel provides greater assurance that the capillary will maintain its function under exposure to corrosive environments.

The effectiveness of stainless steel capillaries in corrosive fluid transfer lies in the alloy’s inherent properties. Chromium content contributes to a passive layer that resists oxidation, while nickel enhances strength and stability against chemicals. This composition allows stainless steel to maintain structural integrity even in acidic or high-temperature environments. When combined with industrial needles, the material’s resilience helps maintain accuracy over repeated use without significant wear.

While material choice is important, the structural dimensions of stainless steel capillaries also determine their suitability for corrosive fluid transfer. A smaller inner diameter allows for precise flow regulation but may increase the risk of clogging if the fluid carries particles. Thicker walls provide added resistance to pressure but reduce flexibility in system design. Therefore, selecting the correct combination of diameter and wall thickness ensures that the capillary not only withstands corrosive fluids but also integrates smoothly into the wider system. This balance becomes especially important when capillaries work alongside industrial needles, as any mismatch could disrupt flow consistency.

In fluid transfer systems, stainless steel capillaries do not function in isolation. They connect with pumps, valves, sensors, and dispensing devices, meaning compatibility is essential. For example, if a capillary with the wrong inner diameter is chosen, it could cause turbulence or pressure loss that affects system accuracy. In chemical processing plants, maintaining stable flow rates prevents disruptions in reaction processes. In laboratory setups, stainless steel capillaries allow researchers to handle aggressive solvents without compromising the validity of results. Industrial needles often rely on capillaries for precise delivery, and stainless steel ensures both durability and consistent performance.

When selecting stainless steel capillaries for corrosive fluids, users should evaluate not only chemical compatibility but also operating conditions such as pressure, temperature, and expected lifespan. Data sheets provided by manufacturers often include information on corrosion resistance, tensile strength, and flow characteristics. Reviewing these specifications before purchase helps ensure that the component will meet the demands of the system. Users should also consider maintenance practices; regular inspections and cleaning can extend the service life of stainless steel components and prevent blockages or buildup inside the tubing.

The versatility of stainless steel capillaries can be seen across industries where corrosive fluids are common. In pharmaceutical production, they help deliver solvents used in extraction and purification. In petrochemical environments, capillaries are used for sampling and analysis of aggressive hydrocarbons. In water treatment facilities, they assist in dosing chemicals that would otherwise damage less durable materials.

Selecting stainless steel capillaries for corrosive fluid transfer is less about preference and more about necessity in systems where material failure is not an option. Their structural strength, resistance to chemical attack, and adaptability make them a practical choice for industries that demand both accuracy and longevity in fluid handling. By assessing application requirements carefully, users can ensure that these components contribute effectively to the stability and efficiency of their systems.

Wenzhou Kangyu Medical TREATMENT

+86-0577-86858771

+86-13957709138

No. 626 Airport Avenue, Longwan District, Wenzhou City, Zhejiang Province, China

Contact Us