+86-0577-86858771

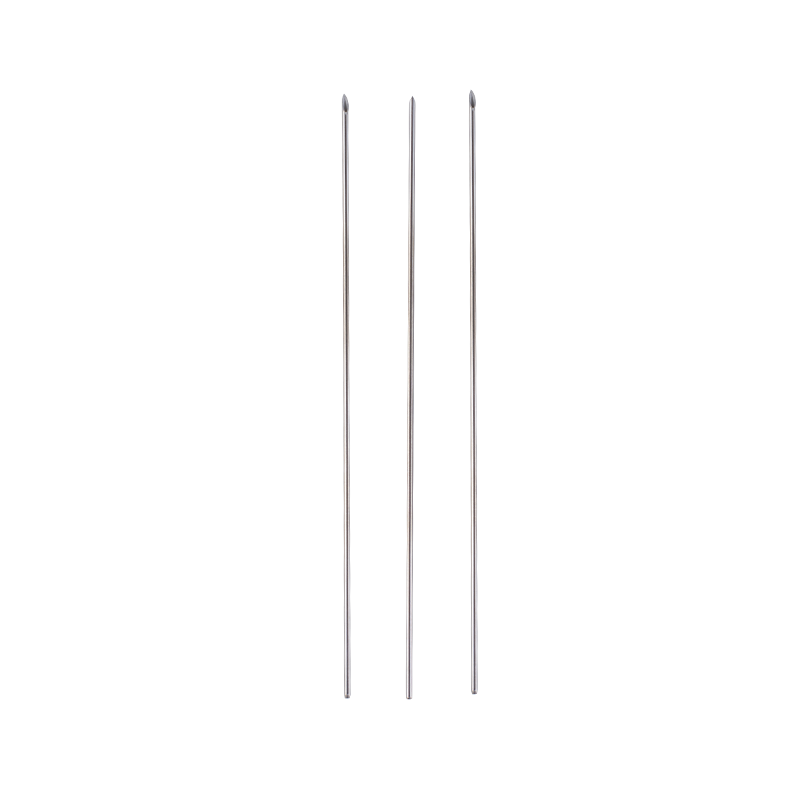

In the healthcare industry, medical needles are an essential component used daily across various medical procedures. The steady and growing global demand for these needles reflects their critical role in patient care, ranging from simple injections to complex surgical applications. Meeting this demand requires a consistent supply of high-quality products such as anesthesia needles, sterile needles, and hollow point needles, each designed for specific medical purposes.

Anesthesia needles play a crucial role in delivering local or regional anesthesia during surgical or diagnostic procedures. These needles are specifically designed to provide smooth, precise administration of anesthetic agents with less patient discomfort. Their size, length, and gauge vary depending on the targeted nerve or tissue area, allowing medical professionals to tailor anesthesia delivery to individual patient needs. The design and manufacture of anesthesia needles focus on sharpness and smooth penetration to reduce tissue trauma and improve overall patient experience. This attention to detail helps ensure the effective delivery of anesthesia while supporting patient safety.

Sterile needles are a fundamental requirement in medical environments to prevent infections and ensure patient safety. The sterilization process eliminates any microbial contamination that could cause complications during medical procedures. Medical facilities rely heavily on sterile needles for vaccinations, blood draws, intravenous therapy, and other routine medical tasks. The production of sterile needles follows strict protocols to maintain sterility from manufacturing through packaging and distribution. This process helps reduce the risk of contamination, cross-infection, and healthcare-associated infections. Given the critical importance of sterility, manufacturers invest in validated sterilization techniques such as gamma irradiation, ethylene oxide treatment, or steam sterilization, depending on the material and needle type.

Hollow point needles serve unique purposes, particularly in procedures that require controlled fluid delivery or aspiration. These needles have a hollow bore that allows fluids or medications to pass through efficiently. In many diagnostic and therapeutic applications, hollow point needles facilitate the collection of bodily fluids like blood or cerebrospinal fluid or the injection of substances directly into tissues. The precise manufacturing of hollow point needles ensures consistent bore size and smooth edges, which help less tissue damage and improve the accuracy of fluid flow. Their design is essential for procedures that depend on reliable and controlled needle function.

Meeting the global demand for medical needles is a complex challenge influenced by factors such as population growth, expanding healthcare access, and increasing prevalence of chronic diseases. For example, vaccination campaigns around the world require billions of sterile needles annually, emphasizing the need for a stable and scalable supply chain. Additionally, the rising use of minimally invasive surgical techniques has increased the demand for specialized needles such as anesthesia and hollow point needles, which support targeted delivery and precision.

To address this demand, manufacturers adopt advanced materials and production methods that prioritize consistency, safety, and functionality. Stainless steel remains the preferred material for medical needles due to its strength, corrosion resistance, and biocompatibility. Innovations in needle design include coatings to reduce friction, improve glide, and enhance patient comfort. Automated manufacturing lines help maintain tight quality control, reducing variability and ensuring needles meet precise specifications.

Logistics and supply chain management also play an important role in ensuring timely delivery of medical needles to healthcare providers worldwide. With the increasing need for sterile single-use needles, packaging and distribution must be designed to preserve sterility and prevent damage during transit. Collaboration between manufacturers, distributors, and healthcare organizations supports efficient inventory management and reduces shortages.

Environmental considerations are becoming more prominent as well, with efforts to reduce medical waste and explore biodegradable or recyclable materials for needle components and packaging. Although safety and sterility remain paramount, sustainable practices are gradually influencing production and disposal processes in the medical needle industry.

In summary, meeting the global demand for medical needles involves a coordinated effort across design, manufacturing, sterilization, and distribution. Products like anesthesia needles, sterile needles, and hollow point needles fulfill vital functions in medical care, requiring precise engineering and rigorous quality standards. The continued evolution of medical practices and growing healthcare needs ensure that the production and supply of these needles will remain an important focus for the industry in the years ahead.

Wenzhou Kangyu Medical TREATMENT

+86-0577-86858771

+86-13957709138

No. 626 Airport Avenue, Longwan District, Wenzhou City, Zhejiang Province, China

Contact Us