+86-0577-86858771

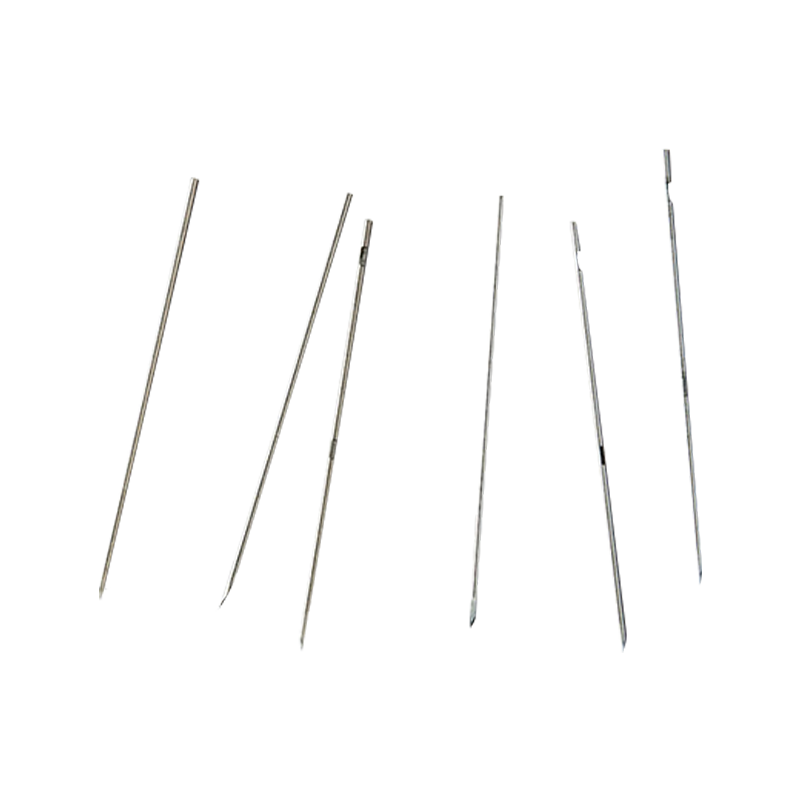

The world of medical technology is constantly evolving, and the manufacturing of medical needles is no exception. From standard needles to specialized tools like needle for blood extraction and injection needle for animals, the industry has seen significant developments aimed at improving patient comfort, precision, and manufacturing efficiency. These innovations are the result of years of accumulated expertise, material advancements, and a better understanding of both human and animal healthcare needs.

Standard needles, long a staple in clinical and hospital environments, have been refined over time to enhance reliability and consistency. These needles are used across a broad range of medical applications including injections, fluid withdrawal, and sample collection. The focus in manufacturing has shifted from simply creating functional products to designing needles with higher sharpness and small invasiveness. Improvements in bevel grinding techniques and stainless-steel tubing allow manufacturers to produce finer tips, reducing discomfort during use. In addition, coatings such as silicone or proprietary glide-enhancing finishes are commonly applied to ensure smoother penetration and lower tissue resistance. These small but significant changes contribute to a better experience for both patients and medical professionals.

For procedures involving blood collection, the design of needles takes on an even more crucial role. Needles for blood extraction are expected to perform with accuracy, small trauma, and consistent flow. Typically equipped with side holes or multi-bevel designs, these needles help ensure that blood is drawn quickly and efficiently without causing excessive pain or damage to the vessel. Manufacturers often work closely with clinical practitioners to develop features such as transparent hubs for visual confirmation of blood flow, luer-lock fittings for secure connections, and varying gauge options to suit different patient populations. Pediatric and geriatric patients, for instance, require different needle configurations than adults due to vessel fragility and size. As such, blood extraction needle manufacturing has become a fine balance between engineering precision and practical healthcare requirements.

Another area of needle manufacturing that continues to gain importance is veterinary care. Injection needles for animals are used in a wide variety of applications, from routine vaccinations to the administration of medications in large livestock. While similar in structure to human-use needles, veterinary needles must be adapted to different anatomical and behavioral challenges. For instance, administering an injection to a restless sheep or a large cow requires a sturdy needle that can penetrate thicker skin and deliver medication effectively. The gauge, length, and durability of the needle must all be carefully considered, as animals may react differently to injections compared to humans. In recent years, manufacturers have introduced color-coded needle systems, ergonomic hubs, and reinforced shafts to improve handling and efficiency in field conditions. These enhancements are especially valuable in rural or outdoor environments where conditions are less controlled than in hospitals or clinics.

One common thread across all categories—standard, blood extraction, and animal injection needles—is the shift toward customization and user-driven design. Rather than producing generic products for all applications, modern manufacturers often create needle solutions tailored to specific use cases. This includes sterile packaging variations, compatibility with different syringes or infusion systems, and integration with safety features such as retractable tips or shields to prevent accidental needle sticks. Regulatory compliance also plays a role, as manufacturers must adhere to strict quality and safety standards during production, from raw material sourcing to final sterilization and packaging.

Behind every medical needle lies a deep layer of engineering and quality control. Sophisticated inspection systems using laser micrometers, camera-based vision, and air-leak tests ensure that each needle meets tight dimensional and performance criteria. Automation and robotics have also become integral to the production process, enhancing consistency while reducing human error. These technologies not only improve production rates but also contribute to overall safety and performance.

In summary, innovations in medical needle manufacturing are driven by the practical needs of patients, healthcare workers, and veterinarians alike. Whether it’s a standard needle used in a daily clinic or a robust injection needle for livestock in the field, the focus remains on delivering efficient, precise, and safe solutions. With ongoing research and advancements in materials and processes, the future of needle technology promises to be even more responsive to the diverse demands of modern medicine and animal care.

Wenzhou Kangyu Medical TREATMENT

+86-0577-86858771

+86-13957709138

No. 626 Airport Avenue, Longwan District, Wenzhou City, Zhejiang Province, China

Contact Us