+86-0577-86858771

In modern healthcare, patient safety remains a crucial focus, especially when it comes to invasive procedures involving needles. The use of precision needles has steadily evolved to support safer, more effective medical treatments, reducing discomfort and fewer risks such as infection or tissue damage. Among the commonly used needles, blood extraction needles, needles of injection, and solid needles each play distinct roles in medical practice, and their careful design contributes to better patient outcomes.

Blood extraction needles are fundamental tools in diagnostic medicine. These needles must be designed to puncture veins efficiently while causing small discomfort to patients. Precision in the manufacturing process ensures the needle’s sharpness and smoothness, allowing it to penetrate skin and vein walls cleanly. This reduces the likelihood of bruising or hematoma formation after blood collection. Additionally, modern blood extraction needles often incorporate safety features that help prevent accidental needle sticks, protecting healthcare workers during and after blood draws.

The needle of injection, commonly used to deliver medications or vaccines, also benefits from advances in precision engineering. Injection needles need to balance strength and flexibility while maintaining a fine gauge to lessen pain during administration. A well-designed needle of injection enables healthcare professionals to deliver drugs at the right depth and speed, optimizing absorption and effectiveness. Moreover, the sterility and consistent quality of injection needles help prevent complications such as infections, which can arise from poorly manufactured or contaminated products.

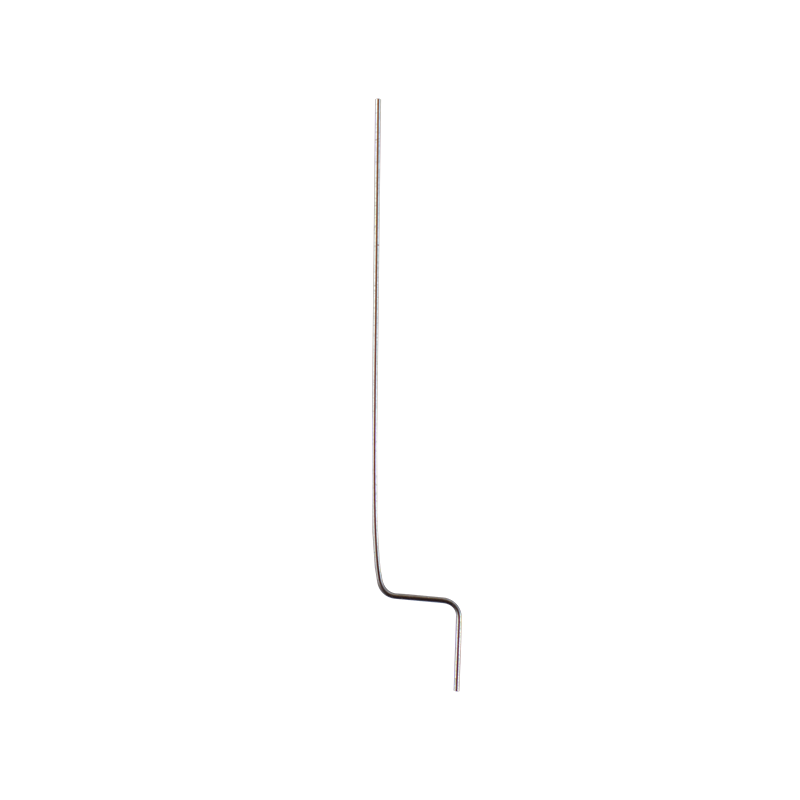

Solid needles, though less commonly discussed outside specialized fields, are essential in certain medical and therapeutic applications. Unlike hollow needles used for injections or blood draws, solid needles are often employed in procedures such as acupuncture or intramuscular stimulation. Their structure demands careful attention to dimensions and finish to avoid unnecessary tissue trauma. Precision solid needles provide practitioners with reliable tools to stimulate targeted areas with small discomfort, supporting therapeutic goals.

The common thread among these types of needles is the emphasis on precision in their design and manufacture. Needle geometry, including bevel angle, tip sharpness, and surface finish, all contribute to patient comfort and procedural success. A needle that glides smoothly through tissue reduces pain and tissue damage, which not only benefits patients but can also reduce anxiety associated with needle procedures. Precision also ensures consistency across batches, which is crucial for maintaining trust and reliability in healthcare settings.

Safety mechanisms integrated into needles have also seen significant improvements. Many blood extraction needles now include retractable or shielded tips that activate immediately after use. This feature helps prevent accidental needle sticks, a serious hazard that can expose healthcare workers to bloodborne pathogens. Similarly, injection needles may come with safety guards or caps designed to reduce exposure risks. These safety-focused designs represent an important step forward in protecting both patients and medical staff.

Another aspect worth noting is the role of material selection in needle production. Stainless steel remains the standard for its combination of strength, corrosion resistance, and biocompatibility. Advances in material processing and quality control contribute to needles that maintain sharpness and structural integrity throughout their intended use. For solid needles, additional surface treatments may enhance smoothness, reducing friction during insertion.

In terms of patient experience, precision needles contribute to smoother procedures that cause less pain and trauma. This can be especially important for patients requiring frequent blood tests or injections, such as those managing chronic conditions. Reduced discomfort may encourage better compliance with medical advice and treatment schedules, indirectly supporting overall health outcomes.

Finally, ongoing research and development continue to refine needle designs. Innovations include exploring new materials, improved bevel shapes, and coatings that less friction or reduce the risk of infection. While these developments are gradual, their cumulative effect is a gradual enhancement of patient safety and comfort.

In summary, the careful engineering of blood extraction needles, needles of injection, and solid needles plays a significant role in modern healthcare. By focusing on precision, safety features, and quality materials, manufacturers support safer medical procedures that reduce risks and improve the overall experience for patients and healthcare workers alike. These advances remind us that even the small components, like needles, can have a profound impact on patient safety.

Wenzhou Kangyu Medical TREATMENT

+86-0577-86858771

+86-13957709138

No. 626 Airport Avenue, Longwan District, Wenzhou City, Zhejiang Province, China

Contact Us