+86-0577-86858771

In fields ranging from healthcare to manufacturing, the role of precision-engineered needles is often understated yet critical. These small components serve as essential tools in medical procedures, industrial processes, and research applications, where their design and functionality directly impact outcomes. Medical needles, tailored for safe and effective patient care, and specialized industrial needles, crafted for specific mechanical or technical tasks, each fulfill distinct purposes while sharing a core requirement: consistent performance. Understanding the differences in their design, materials, and applications helps users select the right tool for their specific needs, ensuring efficiency and reliability in their respective contexts.

Design Considerations for Medical Needles

Medical needles are designed with patient safety and procedural accuracy as primary goals. The choice of material is a key factor, with stainless steel being widely used due to its corrosion resistance, strength, and ability to maintain a sharp point. Needle gauge, which refers to the diameter of the needle, varies based on the procedure: smaller gauges are used for delivering fluids or collecting samples in higher volumes, while larger gauges are preferred for applications like injections where precision and reduced discomfort are priorities.

Another important design feature is the bevel, the angled tip of the needle. The bevel’s shape and angle are optimized to ease penetration through skin and tissue, with different configurations used for specific procedures. For example, longer bevels may be used for intramuscular injections, while shorter bevels are suited for subcutaneous applications. Additionally, some medical needles include features like retractable mechanisms or safety shields, designed to reduce the risk of accidental needle sticks and transmission of pathogens, aligning with infection control protocols in healthcare settings.

Specialized Configurations in Industrial Needles

Industrial needle designs are tailored to meet the specific requirements of industrial applications, which typically involve processing materials such as fabrics, plastics, adhesives, or chemicals. Unlike medical needles, industrial versions may utilize materials other than stainless steel, including high-strength alloys or coated metals, depending on their operating environment—such as exposure to high temperatures or corrosive substances.

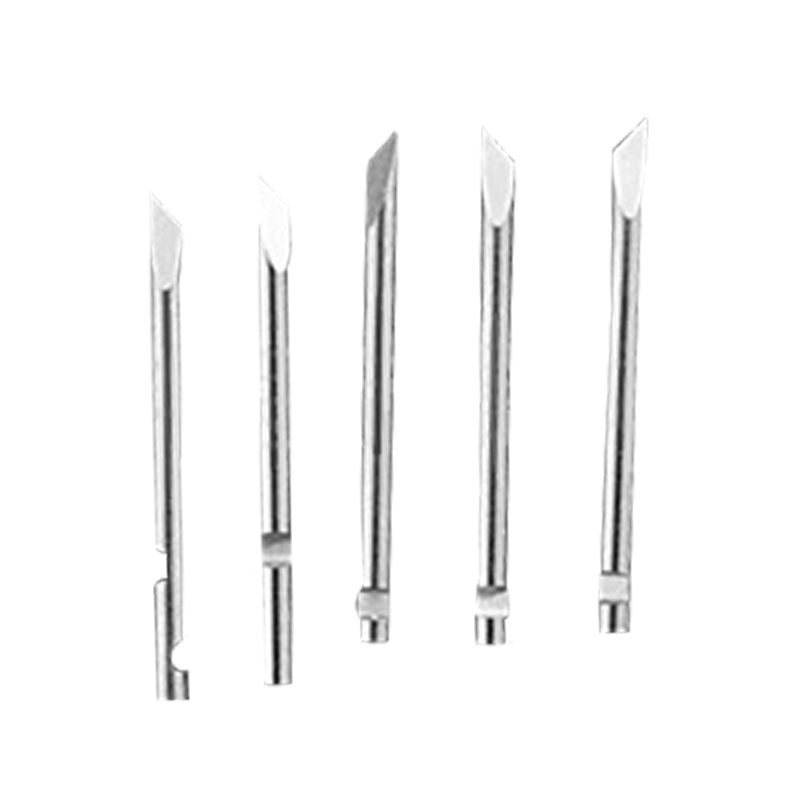

The term "various fancy needles" in industrial contexts refers to non-standard configurations engineered for unique applications. For instance, side-hole needles, which have openings along the shaft rather than just the tip, are used in processes like dispensing adhesives or lubricants, allowing for precise application in hard-to-reach areas. Solid needles, lacking a hollow lumen, find use in tasks like marking materials or creating small punctures in packaging. Industrial needles also vary in length, rigidity, and tip shape: blunt tips may be used to avoid damaging delicate materials, while extra-long needles can reach deep into machinery or containers. These specialized designs ensure that industrial processes can be executed with the precision required to maintain product quality and operational efficiency.

Material Selection Across Applications

Both medical and industrial needles rely on material science to meet their performance requirements. In medical settings, stainless steel remains the standard due to its biocompatibility—meaning it does not react with bodily tissues or fluids—and its ability to be sterilized repeatedly without degradation. This is crucial, as medical needles must withstand rigorous sterilization processes, such as autoclaving, to prevent infection.

In industrial applications, material selection is driven by the task at hand. For example, needles used in chemical processing may be coated with resistant materials to prevent corrosion, while those used in high-speed manufacturing might be made from hardened alloys to withstand repeated use without bending or dulling. Some industrial needles are also designed to be disposable, intended for single use in applications where cross-contamination between materials must be avoided, ensuring consistency in production.

Applications in Diverse Sectors

In industrial settings, the applications are equally varied. Needles are used in textile manufacturing to apply dyes or coatings with precision, in electronics production to dispense solder paste, and in packaging to create vent holes or apply sealants. Industrial-grade needles also find use in research and development, where they assist in small-scale material testing or sample collection. The ability to customize needle configurations—such as length, gauge, and tip design—allows them to adapt to the specific needs of each sector, ensuring reliable performance in highly specialized tasks.

Precision medical needles and specialized industrial needles, through their thoughtful design and material selection, continue to be indispensable tools across a range of fields. Their ability to adapt to specific tasks—whether ensuring patient safety in a clinical setting or maintaining precision in manufacturing—highlights the importance of choosing the right needle for the job. As technology advances, these components will likely evolve further, yet their core purpose remains unchanged: to enable accurate, efficient, and reliable performance in the tasks they are designed to fulfill.

Wenzhou Kangyu Medical TREATMENT

+86-0577-86858771

+86-13957709138

No. 626 Airport Avenue, Longwan District, Wenzhou City, Zhejiang Province, China

Contact Us