+86-0577-86858771

The global supply chain for medical needles has come under increasing scrutiny in recent years, with growing demand for single-use medical devices, expanding healthcare systems, and unforeseen global events all playing a role. Products such as disposable veterinary syringes, disposable needles and syringes, and various needle types have become essential in both human and animal healthcare. However, ensuring consistent availability and quality across regions remains a complex task involving manufacturing, logistics, regulation, and environmental concerns.

One of the primary challenges is the dependency on raw materials and components that are sourced from different parts of the world. The production of needles and syringes often involves stainless steel tubing, high-grade plastics, silicone, and packaging materials. Any disruption in the supply of these can delay production schedules. For instance, the sudden spike in demand during health emergencies can result in shortages of key materials or components, especially when global freight capacity is also strained. The need for medical-grade components further narrows the supplier base, adding another layer of vulnerability.

Logistics also plays a critical role. Disposable syringes and needles require sterile conditions during transportation and storage, which makes logistics planning more demanding. Fluctuating air and sea freight capacities, customs procedures, and temperature control requirements can create bottlenecks. Veterinary and human health sectors often require parallel but separate supply routes, particularly in regions with distinct regulatory requirements. Veterinary-specific products like disposable veterinary syringes may follow different registration processes, making synchronized delivery and distribution more challenging.

Regulatory compliance represents another hurdle. Medical needle products are subject to strict quality control, certification, and labeling standards across various countries. This is especially true for disposable needles and syringes that are meant for direct contact with bodily fluids. The introduction of new labeling requirements or product testing protocols in one region can disrupt the supply chain for months. Manufacturers need to adapt to changing compliance landscapes while also addressing traceability demands and anti-counterfeit measures, which adds to production costs and complexity.

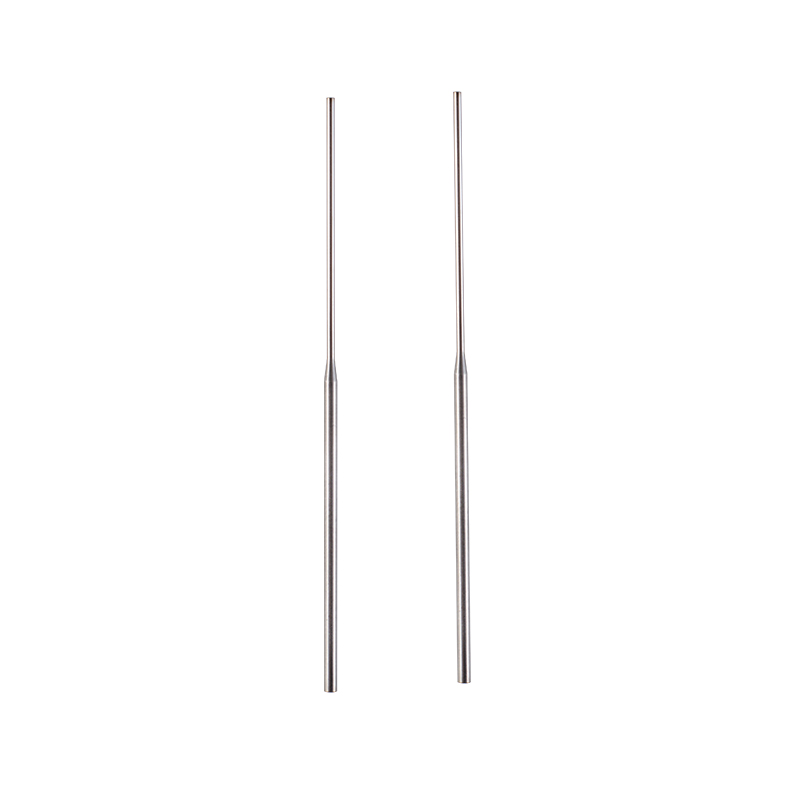

Furthermore, product customization adds another layer of complication. Various needle types are designed for different procedures — from blood collection and fluid injection to vaccination and biopsy. The need to accommodate differences in gauge size, length, bevel type, and compatibility with specific syringes often requires dedicated production lines or adaptable tooling. Smaller healthcare centers and veterinary clinics often request customized kits or packaging quantities, further segmenting the production and fulfillment process.

A growing challenge involves the environmental impact of disposable medical items. The demand for single-use products has risen dramatically due to infection control measures and increased awareness of cross-contamination risks. However, managing the waste associated with billions of used needles and syringes annually is becoming an environmental issue. More governments are tightening regulations around medical waste disposal, and healthcare institutions are looking for suppliers who can support recycling initiatives or use alternative materials. Balancing safety, convenience, and sustainability is not straightforward.

Workforce limitations in both manufacturing and transport also affect reliability. High-precision production of needle products requires skilled labor to operate specialized equipment and maintain stringent hygiene standards. Labor shortages, particularly during public health emergencies or economic shifts, can slow down output and affect product consistency. Likewise, truck driver shortages or port delays can prevent timely delivery, especially for large-volume orders destined for rural or underdeveloped regions.

Finally, supply chain transparency is another area of concern. Distributors and end-users are increasingly demanding real-time visibility into order status, origin of materials, and compliance records. Yet many parts of the medical needle supply chain still operate on outdated systems or disconnected platforms, which can advance to delays, miscommunication, and lack of accountability during recalls or audits.

In conclusion, the supply chain for medical needles — covering items like disposable veterinary syringes, disposable needles and syringes, and various needle types — faces a unique mix of industrial, regulatory, and logistical challenges. Maintaining a consistent, safe, and cost-effective flow of these products requires coordination across continents, compliance with evolving standards, and ongoing investments in both technology and sustainability. As global healthcare needs continue to evolve, so too must the strategies supporting the movement of these small yet critical devices.

Wenzhou Kangyu Medical TREATMENT

+86-0577-86858771

+86-13957709138

No. 626 Airport Avenue, Longwan District, Wenzhou City, Zhejiang Province, China

Contact Us